Welcome to Densmore Tool & Die Works Limited

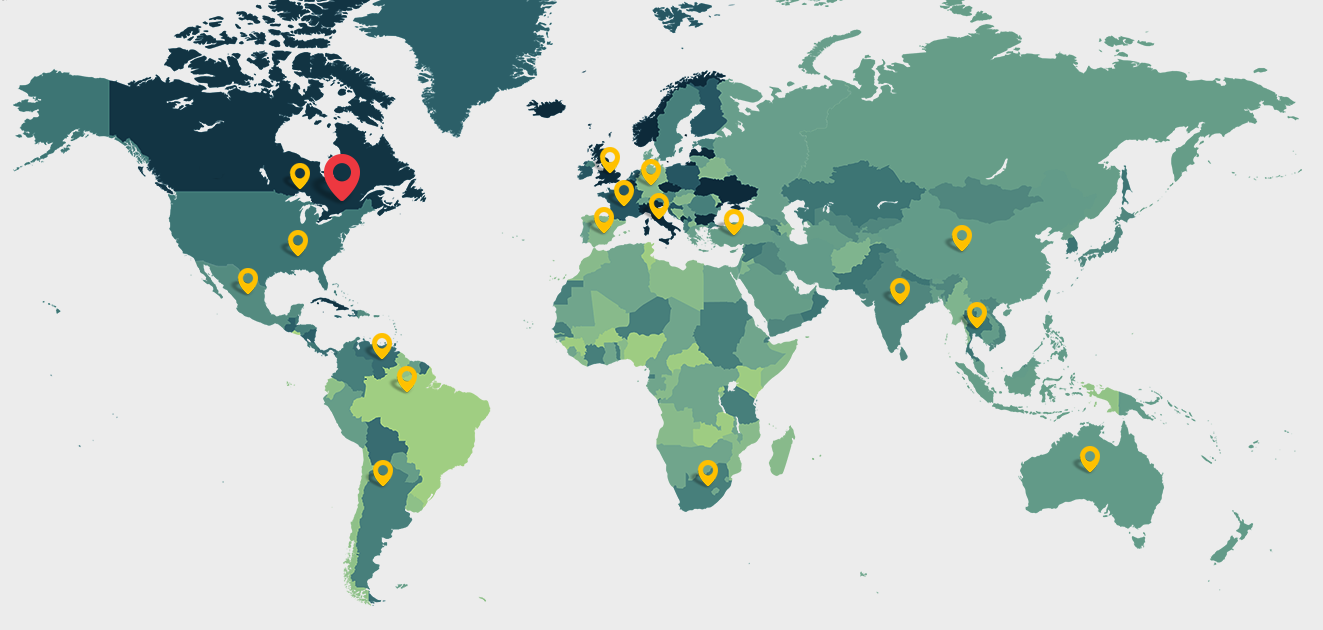

Densmore Tool & Die Works has been in business since 1956, supplying precision custom tooling to the Automotive (Passenger, Light Truck, Medium & Heavy Duty Truck) industry. Densmore Tool & Die Works supplies tooling to clients on a global scale currently encompassing 17 countries and six continents.

Custom Products

Densmore Tool & Die Works supplies tooling for various applications in multiple industries with a focus on meeting and exceeding the unique requirements of customers, regardless of complexity.

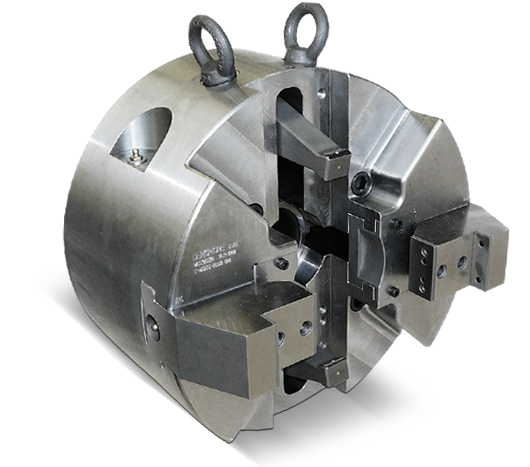

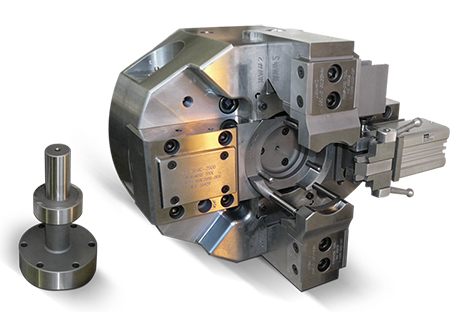

Balancer Fixtures

Supplied globally for over 40 years.

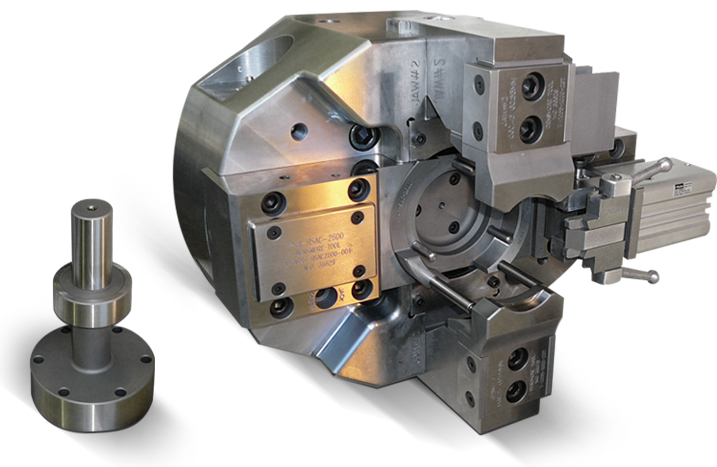

Magnet Arc Weld Fixtures

Robust design with quick change efficiencies and precision.

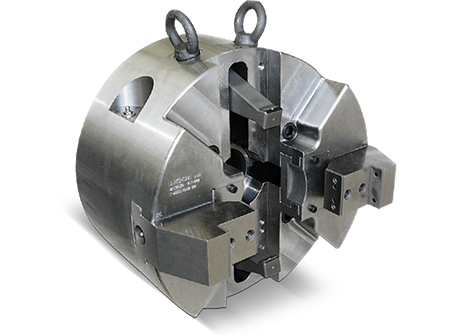

Friction Weld Fixtures

Robust design. Inserts have quick change capability and incorporated centering feature.

Additional products

Upsetter tooling, gauging and can container tooling.

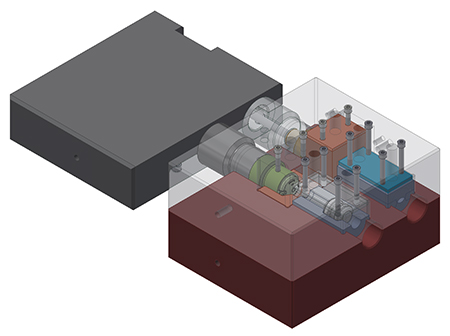

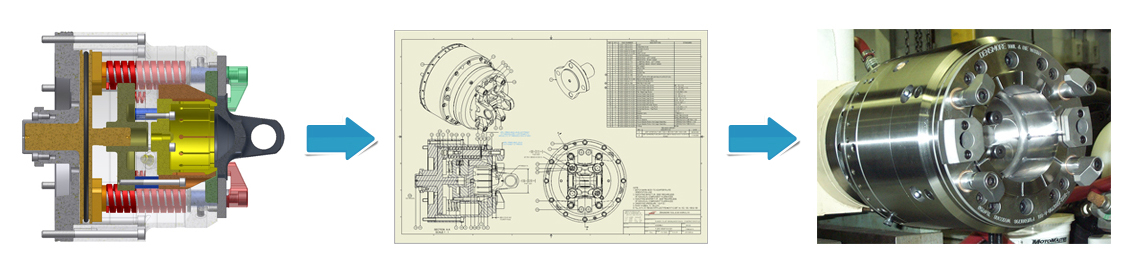

Full Service Provider

Includes the Following:

- Concept Development

- Design / Engineering

- Reverse Engineering

- Solid Modeling

- Full CAD detail drawings provided - unique to the industry

- Manufacturing & Precision Grinding

- Assembly

- Testing & Inspection

- After-sales technical support

- Excellent Customer Communication

Supplying and Servicing Tooling to 17 Countries and 6 Continents

Head Office

Densmore Tool & Die Works Limited2 Hiscott Street

St. Catharines, Ontario

Canada L2R 6T7

Global Customers

- Canada

- Mexico

- USA

- Australia

- Brazil

- China

- Thailand

- England

- Germany

- Italy

- Turkey

- Spain

- India

- Argentina

- Columbia

- Taiwan

- South Africa